Visit the first 5-star 5G factory in China! 2024-11-14 Carol

Video link: https://weibo.com/tv/show/1034:5097400919064606

This year marks the fifth anniversary of 5G licensing and official commercialization. During the past five years, China has built the world's largest 5G network, become the world's first country to build a 5G network based on the independent networking model, 5G network coverage of all municipal urban areas and county urban areas, and 5G technology, with its cutting-edge science and technology, is leading thousands of industries to embark on the “fast lane”.

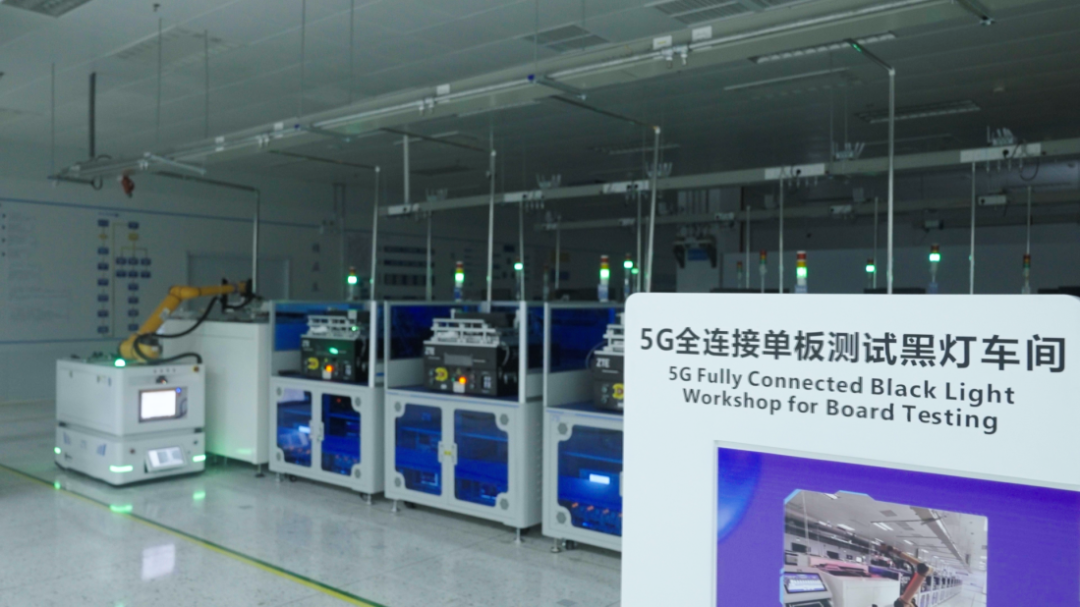

Recently, the construction of ZTE's Nanjing Intelligent Riverside 5G Factory (“Riverside Factory”), the first five-star 5G factory in China, was completed, and it has become a new benchmark for the in-depth integration and comprehensive application of 5G technology and electronic equipment manufacturing.

Flexible Production Lines Make Production More Autonomous

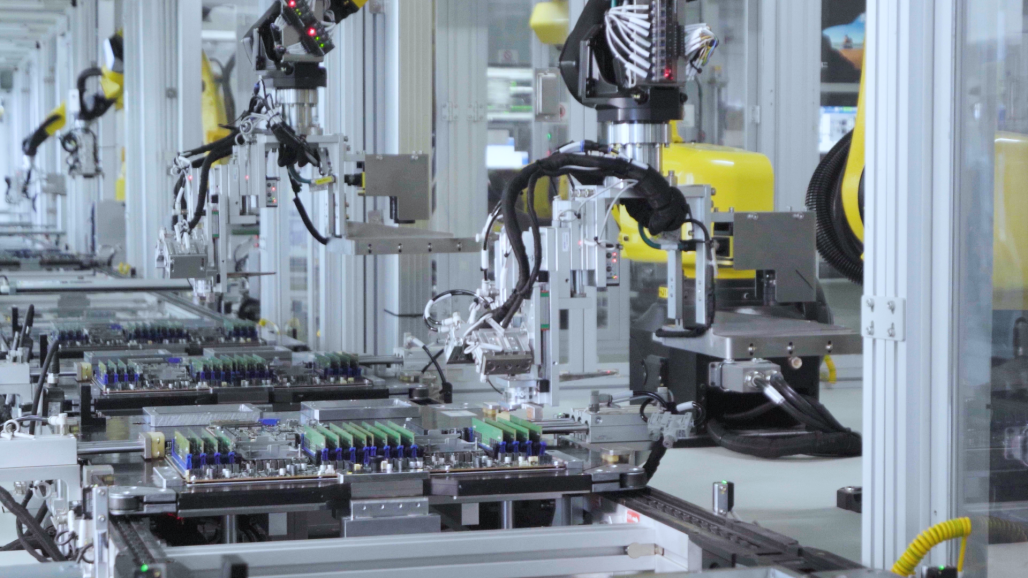

Walking into the factory, several AGV robots are busy and orderly performing various transportation tasks, and their destination is a 100-meter production line consisting of 28 workstations, with rows of robotic arms accurately and efficiently assembling products according to the demands of different orders. This automated assembly line has a unique name in the industry - flexible automated assembly line.

Through 5G CPE technology, the Riverside factory transmits the pictures taken by the high-definition camera on the robotic arm to the backstage for centralized calculation and analysis, and then feeds back to the robotic arm to make movements, realizing the flexible installation of accessories, solving the problem of production efficiency of the traditional production line that needs to be shut down to change the line when dealing with different orders, and letting the machine possess a “brain” and adaptability similar to that of human beings. “and adaptability.

Intelligent logistics makes distribution more accurate

In 16,000 square meters of raw materials in the three-dimensional sorting center, showing in front of the reporter is a high 17 meters, a total of 27 layers of shelves, shelves placed more than 100,000 black boxes. When production orders come in, there is no need for manual picking, and the machine can automatically pick up the materials with zero error. It is an automated and intelligent sorting center created by 5G digital twin intelligent storage equipment. It consists of four parts, including the operation center, 5G air corridor, pallet standing storage system, and AGV goods-to-person and other systems. When the finished product is completed, it automatically runs from the 5G air corridor and arrives at the finished product library for automatic storage, automatic picking and automatic distribution.

“Left and right brain” makes management smarter

In this intelligent factory, will be disassembled into data gathered to the factory's LED screen, each robot distribution, transportation details will form a visualization of the data presented in front of the eyes. iMES intelligent manufacturing platform is like the left brain of human beings, it is connected with the factory equipment, enterprise orders, can collect all kinds of data in the production process, and then through the platform to build the whole factory model, production staff, Management personnel can understand the intelligent operation of the factory more concretely through the platform. The industrial Internet platform is more like the right brain of human beings, playing a synergistic role. It breaks through the boundaries of enterprises, enables upstream and downstream enterprises to interconnect, reduces the trial and error costs of digital transformation, optimizes resource allocation, shares successful experiences, and empowers the real economy.

5G accelerates the empowerment of thousands of industries

Factories use a large number of 5G to transmit field data, which can be more maturely applied in factories, and can take root and spread to more industries. For example, the metallurgical steel industry has a very harsh production environment, and the consideration for personnel safety is very high. The use of 5G technology to do remote control of production equipment, data collection, etc., will be much more efficient than the traditional way to improve the safety of production.

The development of 5G has made remarkable achievements so far, but still faces challenges in some aspects, which should be solved by technological innovation and paradigm innovation. 5G-A comes at the right time, and the future development of 5G-A requires the joint efforts of the whole industry chain. Equipment vendors, service providers, operators and other parties should strengthen cooperation and jointly promote the commercialization of 5G-A. Only in this way can we realize the scale effect of 5G-A and meet the needs of more users.

From 2G follow, to 3G breakthrough, 4G parallel running, and then to 5G base station number, independent network scale, terminal connections jumped to the first place in the world, 5G has become China's scientific and technological self-reliance and self-improvement of the “new business card”. With the accelerated pace of commercialization of 5G-A, its advantages of enhancing 5G capability and paving the way for 6G evolution have gradually come to the fore, accelerating its integration into the real economy, and highlighting the important role of “one industry leads to a hundred industries”.The spread of the new wave of 5G to thousands of industries is also pushing the development of new productivity into an accelerated stage.